It Has Good Mechanical Properties And Heat Resistance, Strong Creep Resistance, Excellent Dimensional Stability, The Best Torsional Strength Plastic, And Continuous Work In High Temperature Water And Steam Is Also Very Stable. Long Service Temperature 170°C. Meet The Requirements Of Biocompatibility And Food Grade Materials.

Characteristic:

Excellent Dimensional Stability, Electrical Insulation, Flame Retardant, Less Burning Smoke, High Temperature Resistance, Radiation Resistance, High Mechanical Properties.

| Shape | Colour | ||

|  | ||

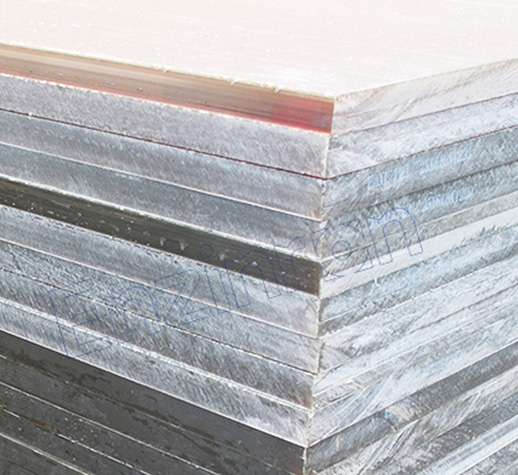

| Plate | Bar | Black | Natural Color |

| Thickness(mm) | Breadth(mm) | Length(mm) |

| 6-100 | 610 | 1220 |

| Diameter(mm) | Length(mm) |

| 6-150 | 1000 |

Specific gravit | ASTM D792 | g/cm3 | 1.27 |

Tensile yield strength | ASTM D638 | Mpa | 110 |

Breaking elongation | ASTM D638 | % | 10 |

Bending strength | ASTM 790 | Mpa | 150 |

Flexural modulus | ASTM 790 | Mpa | 3000 |

Shore hardness | ASTM D2240 | 90 | |

Impact strength | ASTM D256 | J/M | 40 |

Melting point | DSC | °C | 215 |

Heat distortion temperature | ASTM D648 | °C | 210 |

Operating temperature | - | °C | 170 |

Maximum operating temperature | - | °C | 200 |

Themmal conductivity | DIN 52612-1 | W/(K-M) | - |

Coefficient of linear themal | ASTM D696 | Um/m/k | 3 |

Dielectric strength | ASTM D150 | KV-mm | 27 |

Dielectric loss factor | ASTM D150 | - | 0.09 |

| Volume resistivit | ASTM D257 | Ω.cm | 1014 |

Surface resistivity | ASTM D257 | Ω | 1016 |

Dielectric constant | ASTM D149 | - | 3 |

Water absorption | 23°C 60%RH | % | 0.02 |

Acid resistance | 23°C 60%RH | + | |

Alkali resistance | + | ||

Acid and alkali resistance | + | ||

Resistance to sodium chlorate | + | ||

Resistance to aromatic compounds | + | ||

Resistance to ketone | 23°C 60%RH | _ | |

Resistance to hot water | 23°C 60%RH | + |

Flammability | UL 94 | V-0 | |

Viscosity | - | ||

Non toxic | EEC 90/128 FDA | + | |

Coefficient of friction | DIN 53375 | ||

Anti-ultraviolet | - |

plate

Rod

Black

bar

plate

Black